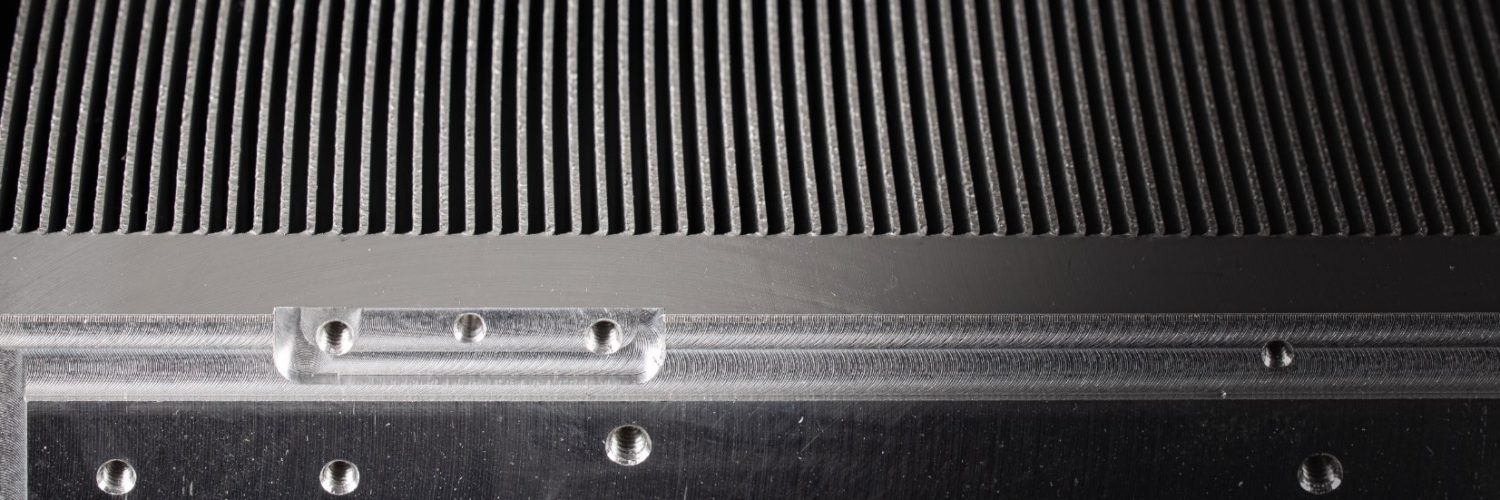

Skiving technology – efficient cooling in a compact size

Smaller element, greater performance! Purso AluCool’s new skiving technology delivers highly efficient and compact cooling elements. Its advantages include a dense fin spacing, excellent heat transfer properties, and low initial costs.

Skiving elements are ideal for applications requiring high cooling capacity, such as renewable energy devices, electronic vehicle charging stations, and 5G base stations. Each cooling element is made from a single, unified piece of metal. Our domestic production caters to both small and large batches.

Lamella solutions

Lamella profiles can be extruded together to create cost-efficient cooling elements with dense fin spacing. While our catalogue includes various standard measurements, we can also tailor other sizes according to customer requirements.

Extruded elements

The extrusion method allows producing cooling profiles of various shapes and sizes and further processing them base on customer needs.

Where are cooling elements the perfect fit?

Purso AluCool’s cooling elements are utilized across various industries. Their excellent heat transfer properties and flexible manufacturing options make them an ideal choice even for the most demanding applications. We design the elements to meet the specific needs of different industrial sectors.

- Power electronics

- Defence industry

- Semiconductor industry

- Battery technology

- Telecommunications

Specialist in cool things

A cooling element for a machine, device or light fitting must be precisely designed to ensure faultless electronic performance in blisteringly hot or arctic cold conditions. Together with our corporate clients’ engineers, we develop the prototypes, test them and ensure their suitability and functionality.

Our global corporate clients never sleep and never stop. That’s why we make sure that we too keep up with all the latest developments. We switched from handwork to automation a long time ago and can deliver products to our contract customers within just one day from receiving their order. Our rate for notices of defects is almost zero, because our manufacture is based on self-monitoring by employees and their diverse professional skills. We stand proud as the guarantors of competitive product excellence for top manufacturers in the global market. If you’re interested in cool things give us a call.